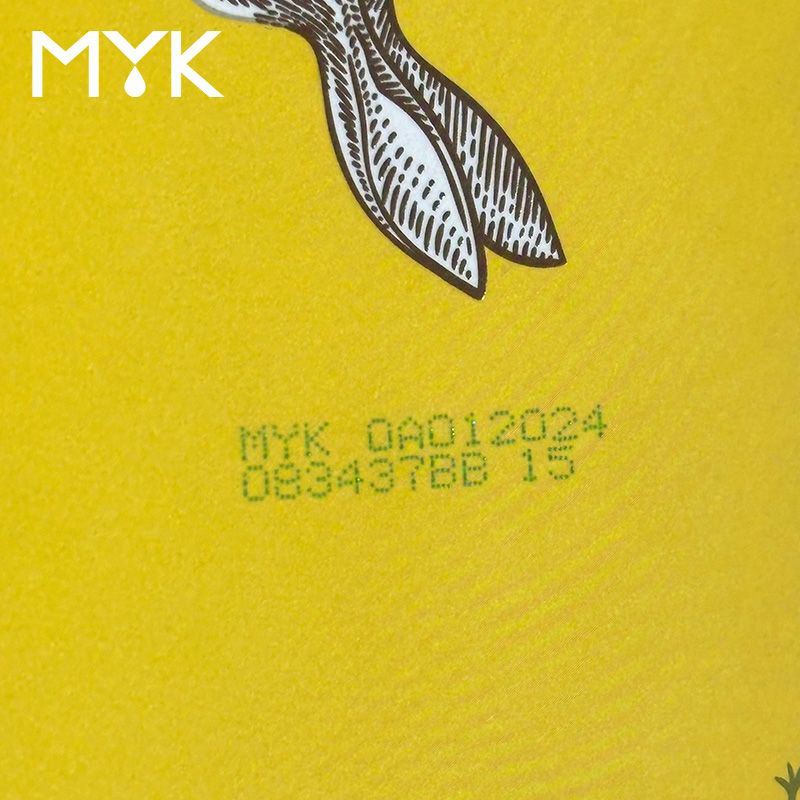

Carton Coding Ink

Carton Coding Ink

1. Superior Adhesion to Diverse Substrates

Strong Bond Formation: The instantaneous UV curing process creates a robust, cross-linked polymer network that chemically and mechanically anchors itself to the substrate surface.

Broad Material Compatibility: This strong adhesion is effective on a vast range of materials—including plastics (e.g., PE, PP, PET), metals, glass, and treated surfaces—where traditional inks often struggle.

2. Exceptional Durability and Abrasion Resistance

High Cross-Link Density: The UV curing process creates a hard, dense, and highly cross-linked film that is resistant to scratching, scuffing, and abrasion.

Surface Protection: The tape-resistant film acts as a protective layer, shielding the printed graphic from mechanical damage during handling, transportation, and end-use.

3. Enhanced Product Quality and Reliability

Image Integrity: Prevents delamination or lifting of the printed image during post-processing steps (e.g., lamination, die-cutting, packaging with adhesive tapes) and throughout the product's lifecycle.

Maintains Aesthetic Appeal: Ensures that logos, text, and graphics remain intact and pristine, preserving brand image and product quality.

4. Resistance to Harsh Environments

Chemical Resistance: A highly cross-linked, tape-resistant film typically also offers excellent resistance to chemicals, solvents, fats, and oils.

Weather and Moisture Resistance: This property often correlates with better resistance to moisture, humidity, and other environmental factors, making it suitable for both indoor and outdoor applications.

5. Facilitates Downstream Processing and Testing

Reliability in Electronics: For printed electronics (e.g., circuit boards), tape resistance is a fundamental requirement to ensure that conductive traces do not peel off during assembly or testing, guaranteeing device reliability.

Passes Standardized Tests: Allows the end product to pass critical industry-standard tests for adhesion and durability, such as the ASTM D3359 (cross-hatch adhesion test) and ASTM F2252 (tape peel test).